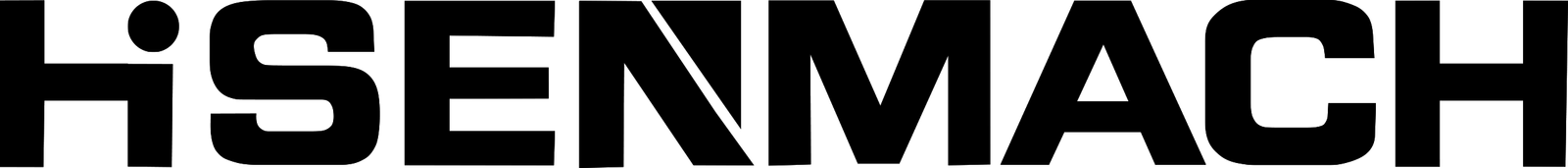

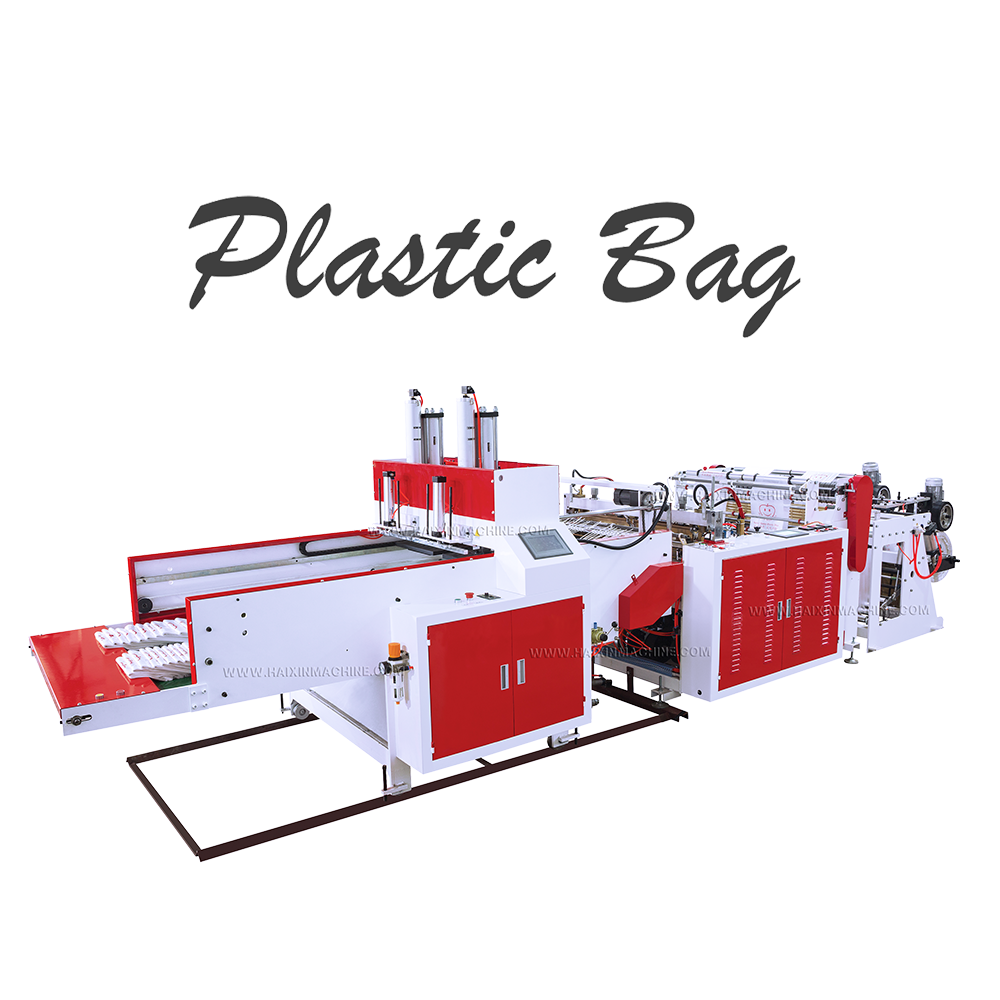

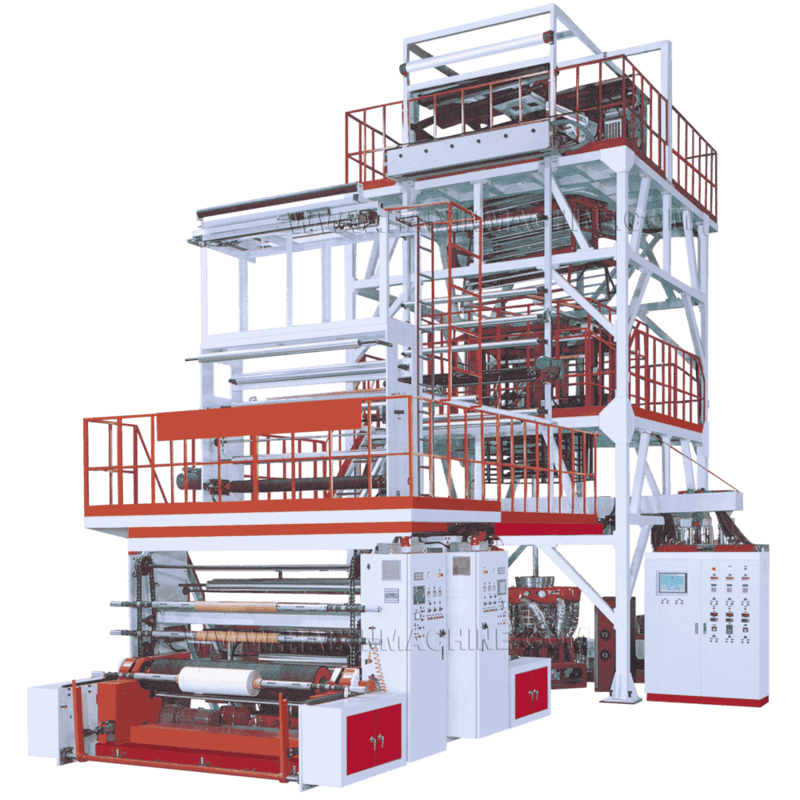

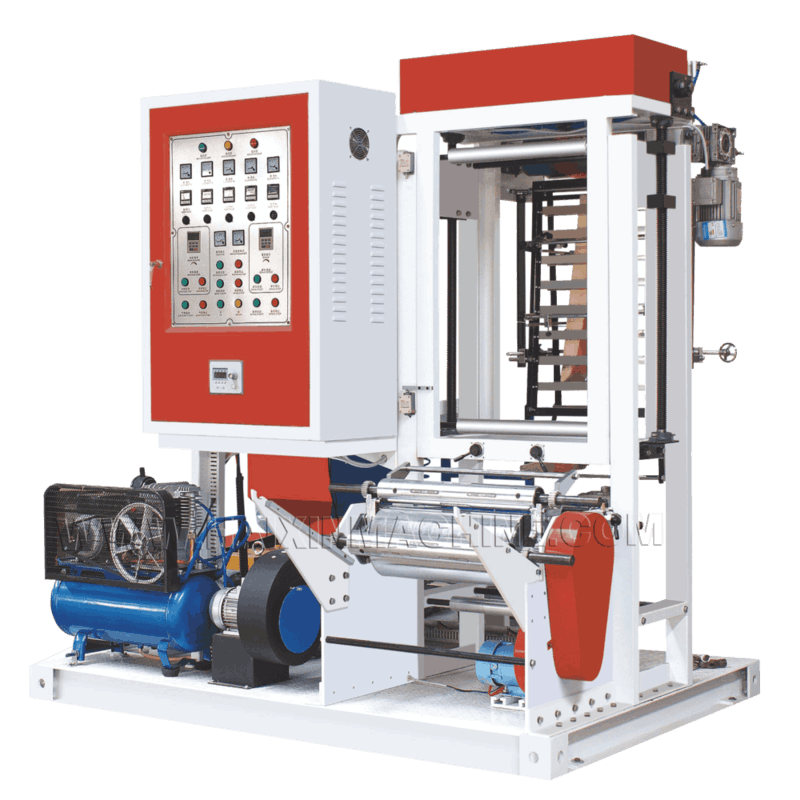

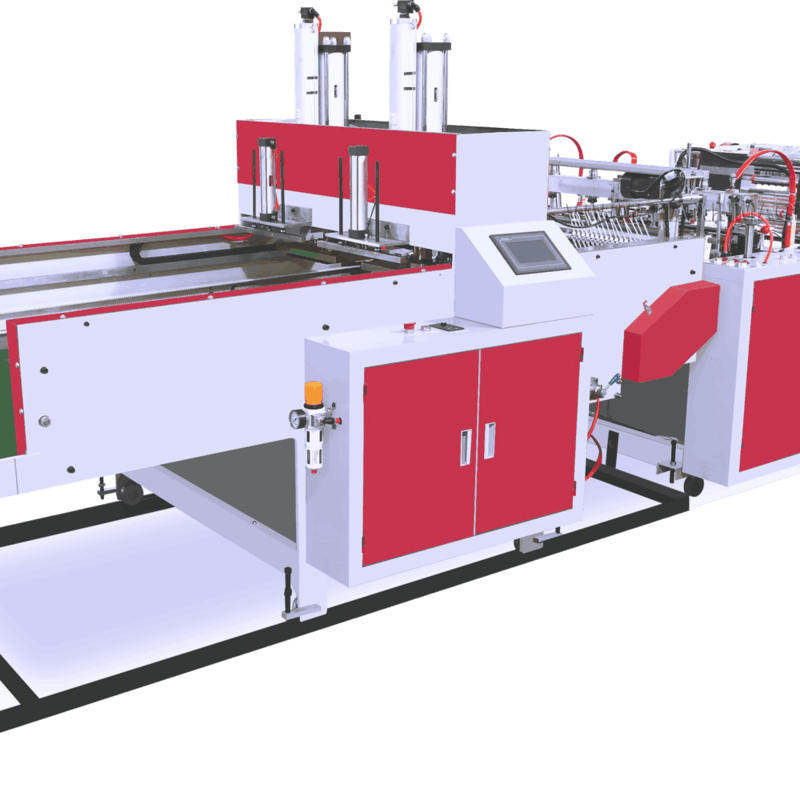

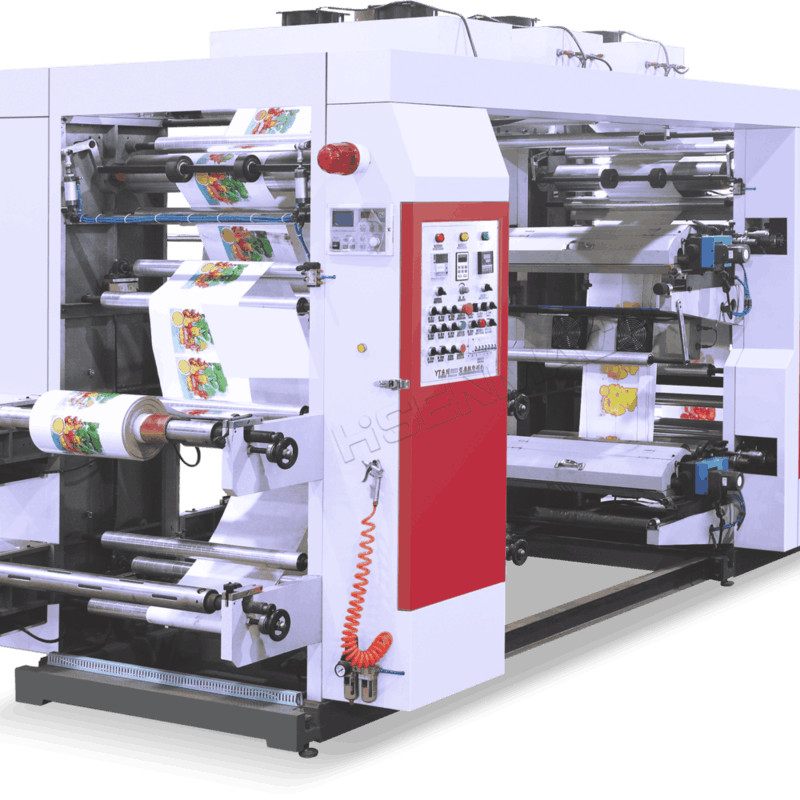

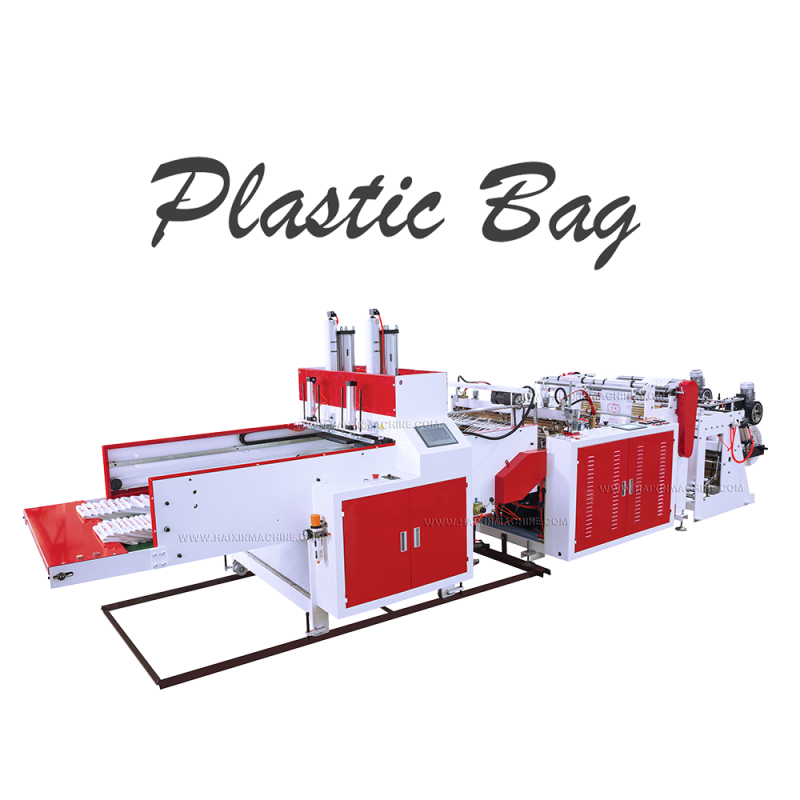

Low Energy Consumption and High Stability of Plastic Bag Making Machines and Blown Film Machines

Introduction

In the modern plastic manufacturing industry, companies face the dual challenges of increasing production efficiency and reducing operational costs. Our plastic bag making machines and blown film machines stand out as industry leaders due to their excellent energy consumption performance and stable production capabilities. This article explores the low energy consumption features, production stability, how to choose the right machines, and the numerous advantages of our products. Additionally, our factory has established a dedicated low energy consumption plan aimed at continuously optimizing equipment performance and enhancing overall economic benefits for our customers.

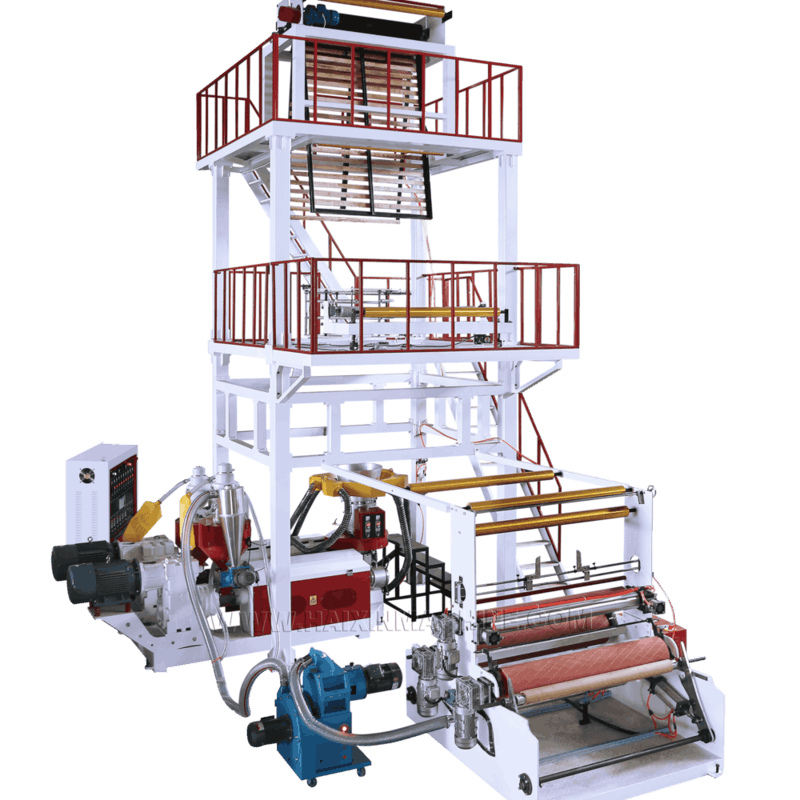

Low Energy Consumption Features

Energy consumption is a critical factor impacting operational costs in the production process. Our plastic bag making machines and blown film machines are designed and manufactured with a strong focus on energy savings, ensuring that we provide our customers with more competitive products.

Our machines use high-efficiency motors from the Inovance brand, typically achieving an IE3 energy efficiency rating. Compared to traditional motors, Inovance motors can reduce energy consumption by approximately 10%-30%, allowing you to significantly lower your electricity expenses.

Equipped with advanced variable frequency drive systems, our machines automatically adjust motor speeds based on production demands. This intelligent control can reduce energy consumption by up to 20%. For example, a standard plastic bag making machine normally consumes 15 kW, but with variable frequency control, actual energy consumption can be lowered to 12 kW.

The equipment maintains a low operating temperature, extending the lifespan of the motor and reducing energy consumption. With optimized design, operating temperatures are typically kept below 60°C.

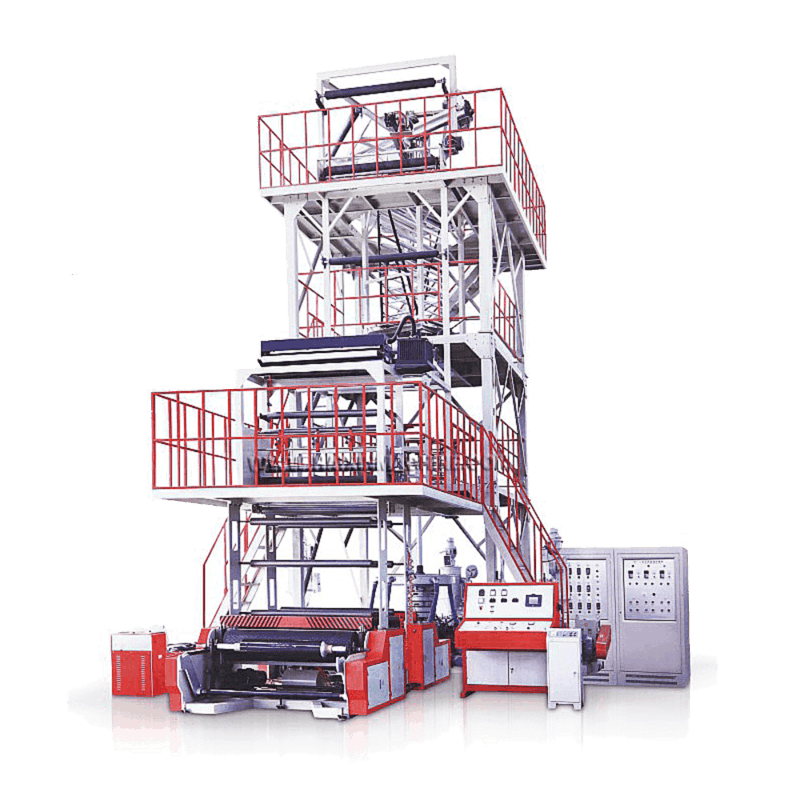

Production Stability

Production stability is a crucial indicator of equipment performance. Our plastic bag making machines and blown film machines excel in terms of stability, ensuring that customers receive high-quality products.

Our machines can produce 400-800 bags per hour, depending on the model and material type. After 12 hours of continuous operation, the production speed remains above 400 bags/hour, with a quality rate of up to 98%.

Equipped with advanced PLC control systems, our machines monitor equipment status in real-time, ensuring quick resolution of issues during production. Core components are made from fatigue-resistant materials, with a lifespan of up to 10 years, reducing maintenance frequency.

Bag making machine which factory is good?

Choosing our plastic bag making machines and blown film machines comes with several advantages. Our machines utilize Inovance motors and advanced drive systems, ensuring high energy efficiency and low consumption, significantly reducing your operational costs. Our equipment performs exceptionally well during production, ensuring that you can consistently produce high-quality products and minimize risks associated with equipment failures. The highly automated design allows you to reduce reliance on labor, enhancing production efficiency. We provide personalized equipment and services based on specific customer needs, ensuring that our machines meet your unique production requirements. Our team offers professional after-sales service to ensure the continuous stable operation of your equipment.

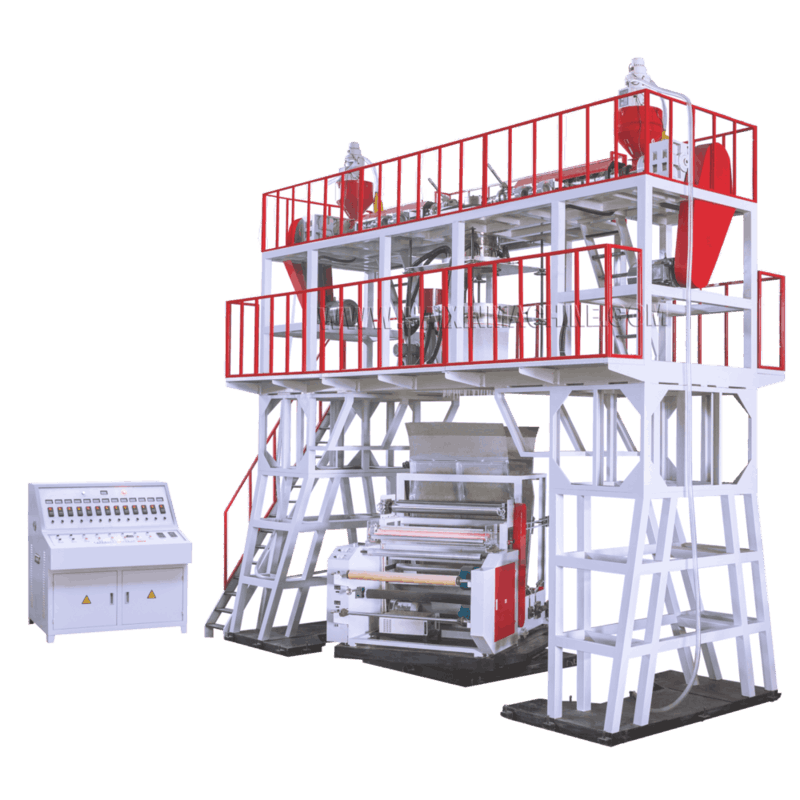

Labor and Cost Savings

Our plastic bag making machines and blown film machines provide significant advantages in labor and cost savings. The high level of automation in our equipment reduces reliance on labor, leading to a 30%-50% decrease in manpower needs. This not only lowers labor costs but also minimizes the risk of human error.

Through intelligent monitoring systems, companies can track equipment status in real-time, enabling timely maintenance and adjustments, thereby reducing downtime. With our equipment, companies can achieve higher production efficiency and lower energy consumption, leading to an overall operational cost reduction of 15%-25%. For instance, after using our plastic bag making machines, a client reported a production cost reduction of nearly 100,000 yuan within six months.

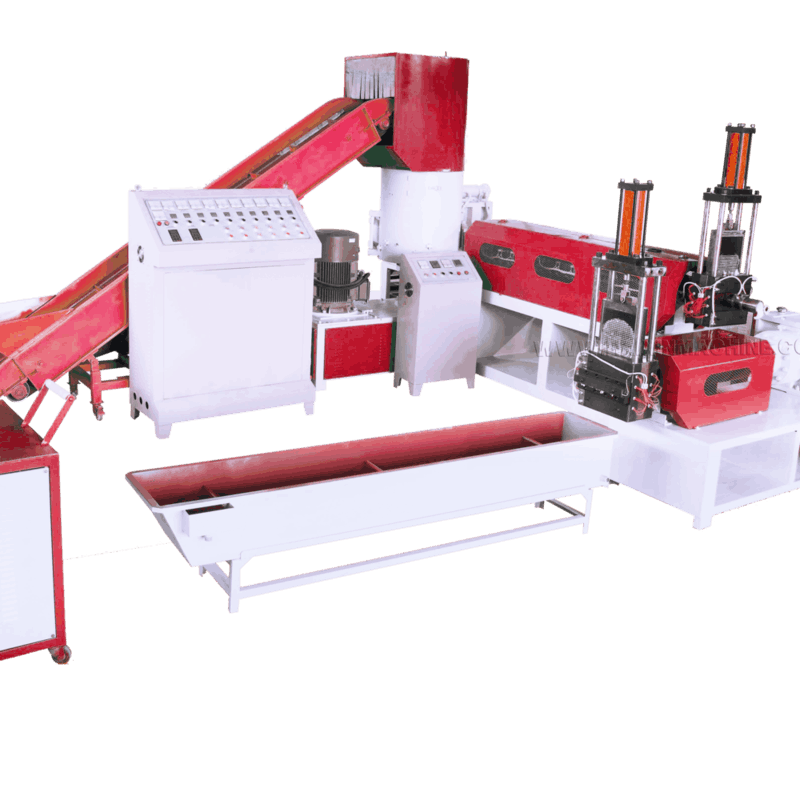

Cooperation Cases

We have established successful partnerships with several large enterprises, showcasing the efficiency and reliability of our equipment.

A global fast-moving consumer goods company improved its production efficiency by 25%, saving over 50,000 yuan in electricity costs per month after adopting our plastic bag making machines.

A major e-commerce platform chose our blown film machines to meet growing packaging demands, successfully doubling its production capacity while saving an estimated 500,000 yuan annually.

An eco-friendly plastic manufacturer collaborated with us to develop a low-energy plastic bag, achieving a 30% reduction in production costs with our plastic bag making machines.

Our Machines’ Numerous Advantages

Our machines ensure high energy efficiency and low consumption, feature intuitive interfaces for easy operation, and offer tailored solutions based on customer needs. They are manufactured with high-quality materials, resulting in a long lifespan and low maintenance costs, while operating noise levels below 70 decibels provide a quieter working environment.

Conclusion

Our plastic bag making machines and blown film machines excel in energy consumption and stability, capable of meeting the diverse needs of modern plastic manufacturing enterprises. By utilizing Inovance motors and advanced control systems, customers can lower operational costs and ensure the stability of product quality. Our established low energy consumption plan will further drive technological innovation and enhance equipment performance, helping clients stand out in a competitive market. For more information or to consult on equipment selection, please feel free to contact us; we look forward to providing you with professional solutions.

Learn More About HSENMACH E-motors Bag Making Machines And Film Blowers